Drilling Machine & Tools ǀ Types & Application

- aathaworld

- Jul 2, 2021

- 4 min read

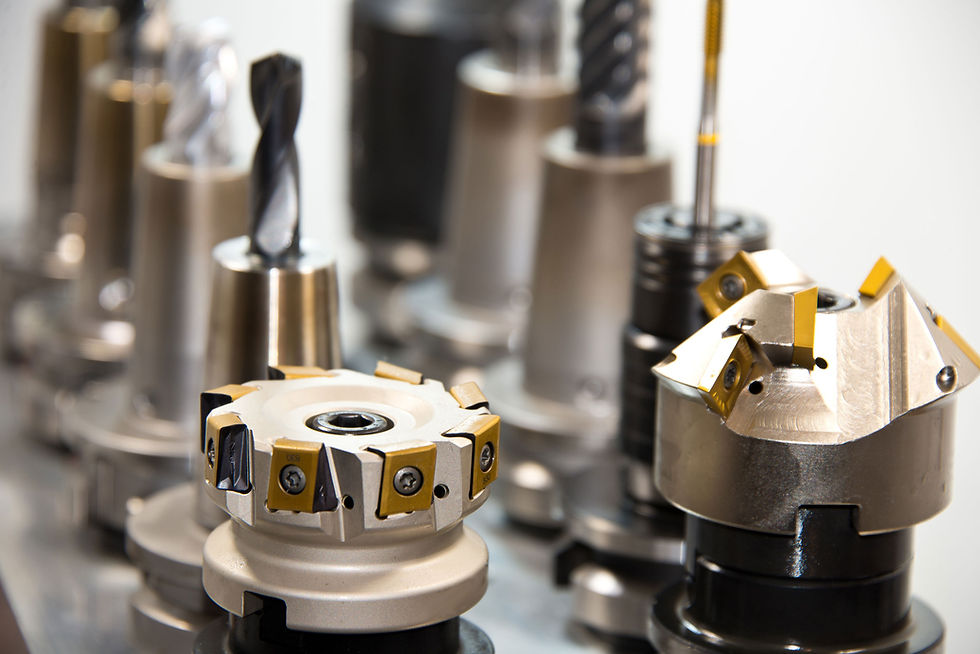

A drilling machine is a cutting tool that is primarily used for making holes of different diameters or enlarging an existing hole in a variety of workpiece materials such as the wood plank, various metal types, plastic, etc. It is a piece of essential equipment used in the manufacturing industry and also used in the repairing of various machinery. Besides that, a drilling machine is also very commonly used in the construction industry. Apart from drilling circular holes, a drilling machine can also perform other functions. For instance, it can be used for counter-boring, countersinking, honing, reaming, lapping, sanding, and other operations. Generally, a drilling machine consists of a base, a pillar, an upper arm, a work-table, a drill head, feed mechanism (electric motor, pulley, V-belt), spindle, drill jigs, chuck, electric motor and gears. There are many types of drilling machines, each serving different purposes with similar functions to meet different demands.

Portable Drilling Machine

The portable drilling machine is commonly used in workshops to bore small holes in the workpiece. It is operated by holding the drilling machine with one hand and holding the workpiece in another and the hole is directly drilled into the workpiece with precision.

Sensitive Drilling Machine

The function of this small drilling machine is to quickly drill holes small enough on a workpiece. There are two types of sensitive drilling machines, namely the bench mounting sensitive drilling machine and the floor column upright drilling machine. As the name suggests, the drilling machine can be either mounted to a bench or on the floor for easier operation.

Upright Drilling Machine

The upright drilling machine is used in boring larger holes in the workpiece. It is a drilling machine that is larger and is stronger when compared to a sensitive drilling machine. The round column upright drilling machine and the box column upright drilling machine is classified based on the type of column/pillar.

Radial Drilling Machine

Plain drilling machines, universal drilling machines and semi-universal drilling machines are all radial drilling machines. A radial drilling machine is used when work is at a large amount. The radial drilling machines can be arranged to drill anywhere on the workpiece where the machine is able to reach. The movement of the spindle to drill holes can be controlled by the movement of the arm of the drilling machine.

Gang Drilling Machine

A gang drilling machine has a few drill heads built next to each other over the work table. The purpose of the design is to drill multiple holes at the same time on a workpiece or a few workpieces. This machine has the advantage of drilling different sizes of holes on a workpiece at a faster rate.

Multiple Spindle Drilling Machine

This drilling machine is typically used for high production rate of workpieces. The machine is equipped with many spindles attached to the drill head so that multiple holes can be drilled at the same time to the workpiece.

Automatic Drilling Machine

An automatic drilling machine is a machine with multiple functions. Besides its primary function which is drilling, it can be used for honing, milling and other purposes. With this drilling machine, the work can be done without manual handling. This is because this machine allows the work to move from one machine to another machine to perform different operations on the workpiece. The work is transferred from one machine to another machine automatically.

Deep Hole Drilling Machine

It is a machine for metal cutting. As the name suggested, this drilling machine is designed to drill holes that are very deep. In addition, deep hole drilling is normally needed in materials such as barrels, shafts, etc.

On the contrary, a drilling tool is a tool that every homeowner needs at some point but might not realize. For instance, it will be needed if one decides to drill a hole to insert screws on the wall to hang paintings, plants, shelves or for other applications. In addition, a drilling tool can also be used to unscrew screws that are tightly screwed. Needless to say, there are also various types of drilling tools in the market to meet various demands and purposes.

Hand Drill

Hand drill is a tool that is used by many woodworkers, i.e., carpenters. This is a manual drilling tool that is suitable for making a circular hole before inserting a screw. The hand drill is not powered by electricity therefore it is easy to use by simply turning sideways with the drill until the desired depth.

Electric Drill

An electric drill is powered by electricity, either powered by batteries or cable. This drill is more powerful than hand drills and can drill holes faster and deeper. The electric drill can be used on a variety of materials. Apart from drilling, it can be also used for other purposes, such as sanding, grinding and driving screws.

Hammer Drill

A hammer drill, sometimes known as an impact drill, is a drill with hammering action to deliver more power. For that reason, it is normally used to drill through materials such as concrete and masonry that have a very hard surface.

Benchtop Drill Press

A benchtop drill press is a tough tool that is used to drill holes accurately in wood and other materials such as metal or plastic. It can drill different diameters of holes with different types of drill bits through a variety of materials.

Where to Source Driller, Power, Air and Other Hand Tools Supplier in Malaysia

Aathaworld Sdn Bhd supply and install a wide range of drilling tool system or machine who can offers comprehensive setup advisory, fabrication, supply, install, maintenance or upgrading manual one, for your industrial plants, mill, construction sites to factories, or other special retail projects in KL Kuala Lumpur, Selangor, Klang Valley, JB Johor Bahru, Penang, Malacca (Melaka), Seremban Negeri Sembilan, Perak, Pahang, Kuantan, Kelantan, Terengganu, Perlis, Alor Setar Kedah, as well as Sabah and Sarawak for East Malaysia; we can be your drilling machine supplier and tool installer for other regions such as in Southeast Asia (SEA) including Singapore, Myanmar (Burma), Cambodia, Vietnam, Laos, Thailand, Indonesia, Philippines, Brunei, Bangladesh as well as China, Taiwan, Hong Kong, Australia and New Zealand.

Submit your hand tool, air pneumatic products or drilling machine sourcing requirements (supply and maintenance), either you are looking for a supplier or contractor for new ancillary accessories in addition to main equipment or for the repair services in KL Kuala Lumpur, Selangor or other states in Malaysia. Submit your pneumatic, air compressor set, hand and power tool sourcing requirements enquiry now to info@aathaworld.com or call (WhatsApp) to +(60)11-7001 1003 (Monday to Friday) or +(60)11-1188 1003 (Saturday, Sunday & Public Holidays).

Photo credit: media from wix, imts, pickadvisor, keil

Comments